Bioengineering and medical devices

Release time:

2018-10-16

Bioengineering is a hotspot in the field of scientific research in recent years. With the development of science and technology, the accuracy requirements of medical devices are getting higher and hig

Bioengineering and medical devices

Application of ultrasonic motor in bioengineering and medical equipment Bioengineering is a hotspot in the field of scientific research in recent years. One of its characteristics is the requirement for ultra-precision, such as precision drive platforms and precision feed devices. The ultrasonic motor has fast response and high positioning accuracy, which makes the ultrasonic motor attract wide attention from bioengineering researchers all over the world.

Application of ultrasonic motor in bioengineering and medical equipment Bioengineering is a hotspot in the field of scientific research in recent years. One of its characteristics is the requirement for ultra-precision, such as precision drive platforms and precision feed devices. The ultrasonic motor has fast response and high positioning accuracy, which makes the ultrasonic motor attract wide attention from bioengineering researchers all over the world.

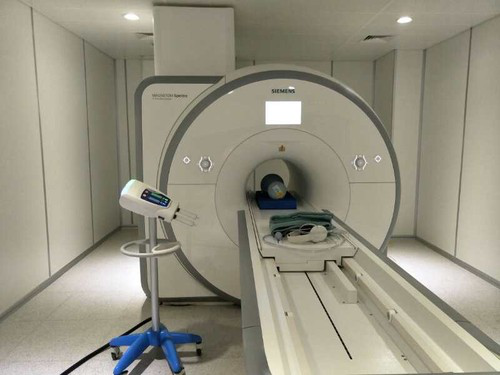

MRI is a new medical imaging technology using the principle of nuclear magnetic resonance. It is excellent for the brain, thyroid, liver, gallbladder, spleen, kidney, pancreas, adrenal gland, uterus, ovary and other vital organs as well as the heart and large blood vessels. Diagnostic function. Compared with other auxiliary inspection methods, nuclear magnetic resonance has the advantages of many imaging parameters, fast scanning speed, high tissue resolution and clearer image. It can help doctors “see” early-onset lesions that are not easily noticeable. It has become a tumor, heart disease and A tool for early screening of cerebrovascular diseases.

Since the metal will interfere with the external magnetic field, the patient must remove all the metal objects on the body before performing the MRI. The patient needs to inject contrast medium during the MRI examination. The injection requires constant speed propulsion. The best way is to use a motor to drive at a constant speed. However, the traditional motor itself generates a magnetic field, which has an adverse effect on real-time imaging. In the prior methods, some use manual injection methods, and some use long guide rods to isolate the electromagnetic motor from the nuclear magnetic resonance equipment.

However, ultrasonic motors do not have such problems. Compared with conventional electromagnetic motors, ultrasonic motors do not rely on electromagnetic interaction to transfer energy. Rather, the microscopic vibration excited by the inverse piezoelectric effect of the piezoelectric ceramic is used as a driving force, and is converted into a macroscopic motion of the rotation of the rotor by resonance amplification and friction coupling. The ultrasonic motor itself does not generate a magnetic field and is not affected by the magnetic field. It is very suitable for nuclear magnetic resonance. The ultrasonic motor can be used to complete the injection process.

Ultrasonic motors have no windings and no electromagnetic fields, making them the first choice for executing motors in nuclear magnetic resonance medical equipment. Ultrasonic motor has low speed, high torque, no electromagnetic interference, fast response, no noise operation, self-locking power failure, etc., which makes it more advantageous than traditional motors in medical equipment and other fields.

Related Applications

hj@hjqp.cn ywj@hjqp.cn

hj@hjqp.cn ywj@hjqp.cn

0511-86355528

0511-86355528

在线留言

在线留言