Optical Instruments

Release time:

2018-10-16

The function of modern optical instrument has become the extension and expansion of human brain nerve function. With the development of science and technology, the demand for its accuracy is gradually

Application of ultrasonic motor in optical instruments

First, optical microscope

An optical microscope is an optical instrument that uses optical principles to magnify and image small objects that cannot be distinguished by the human eye for people to extract fine structure information. Many scientific experiments need to be done with the aid of a microscope, and the performance of the microscope is the key to doing an observation experiment.

The microscopic platform of high-end microscopes is generally driven by a motor, but based on the defects of the traditional motor itself, the accuracy often fails to meet the requirements, or it can be achieved through a very complicated design, while the vibration of the traditional motor works for the high-end microscope. It is also fatal. When observing the vibration of tiny objects, such as cell fluid, it will affect the results of experimental observations. However, if the micro-platform driven by the ultrasonic motor is used, based on the advantages of high positioning accuracy and small vibration of the ultrasonic motor, the above two points can be completely overcome, and the experimental observation effect is better.

Features of the electric optical microscope working platform

★Mute: Driven by ultrasonic motor, no noise (within 10cm, 45dB running).

★Non-magnetic: driven by ultrasonic motor, no coil magnetic field, no magnetic field interference.

★Smooth: It is driven by ultrasonic motor, no need for deceleration structure, high reliability and stable operation.

★Sensitive: Driven by ultrasonic motor, the response is fast (less than 3 milliseconds).

★Accuracy: It is driven by ultrasonic motor and has high controllable precision.

|

|

|

Second, the application of ultrasonic motor drive focusing lens in micro projector

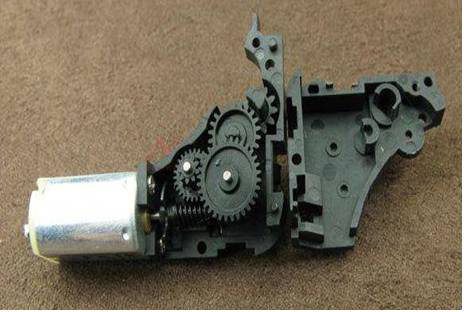

Micro projectors are popular with consumers because of their small size and portability. However, the autofocus lens cannot be used due to the limitation of its volume structure. Conventional projector lenses use a miniature stepper motor or a manual gear set structure for focusing. Disadvantages of stepping motor or manual gear focusing structure: 1. The structure is complicated, the gear set and the motor part are easily damaged, and the failure rate is increased. 2, the volume is large, increasing the internal and external volume of the lens, not suitable for miniaturization of the product. 3. The structure of the focusing part is more expensive to open.

Advantages of using an ultrasonic motor:

1. The ultrasonic motor adopts internal thread structure, and the structure is simple and easy to handle.

2. Ultrasonic motor has the advantages of waterproof, anti-magnetic and dustproof, and is not affected by the use environment.

3. The ultrasonic motor is small in size and does not occupy other space of the whole machine. It is the best choice for miniature lenses.

Advantages of using an ultrasonic motor to drive a focusing lens:

1. Simple structure, no gear transmission mechanism;

2. The focusing part is directly driven by the ultrasonic motor to adjust the lens, thereby reducing the failure rate of the mechanical and electrical parts;

3, using ultrasonic motor drive, eliminating the mechanical part, can reduce the size of the lens group;

4、4.Eliminate the cost of mold opening and effectively reduce manufacturing costs.

Related Applications

hj@hjqp.cn ywj@hjqp.cn

hj@hjqp.cn ywj@hjqp.cn

0511-86355528

0511-86355528

在线留言

在线留言